According to the user's unique demands and machining characteristics, we can directional design ,ressearch and develop non-standard grinding inserts ,tool holders, milling cutters, composite drills, solid carbide endmills, solid carbide drills, solid carbidereamers, etc , then achieve to impove production efficiency and reduce comprehensive costs

General turning & milling threading tools, Oil & Gas threading, Solid carbide threading end mills Tap etc these complete product line can provide wide range choice, to meet the different types of thread processing; Good product surface treatment and minimal processing intervention can provide excellent chip control.

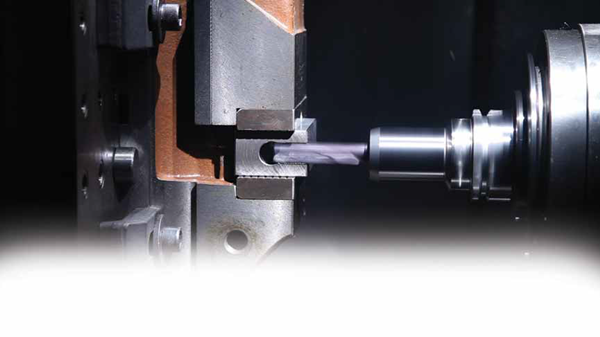

Cover Original Spade Drill, High Speed Drill, V-max Drill, Turbo Drill and Solid Carbide Drill etc; Specail material can ensure the stability and riidity of the drill body; High strength holder is the best choice for the drilling, even in the difficult cutting condition, the outstanding design still can get good cutting performance; Excelletn helical flute design can ensure the longer tool life.

New helix double side milling cutter, high feed milling cutter, nano smurfas end mills etc multi-functional cutters can be used in various applications. They can be not only meet your machining demands, but also improve productivity.

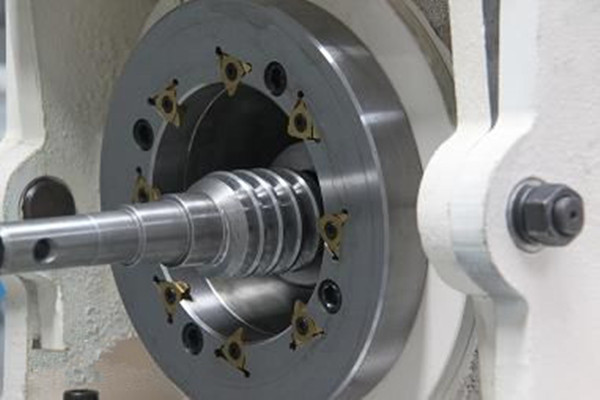

Cover a wide application range with a full-up line of ISO tools to meet all high quality and high precision parts for all the customers' requiremnets.

Mainly deal with manufacturing of twin edge boring tools, single edge boring tools, boring tools for major diameter, minipore boring system, fine boring tools etc.

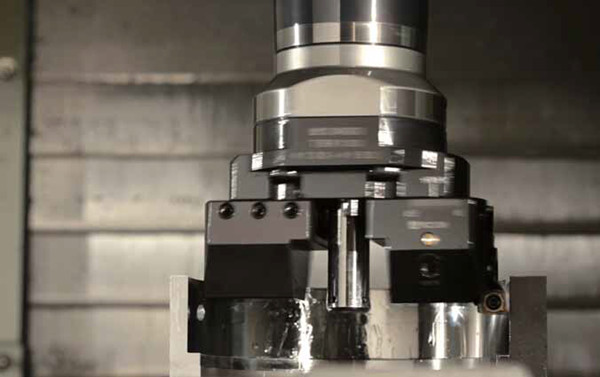

Mainly deal with manufacturing of Modular tooling system, side-lock toolholders, collet chucks, face mill holders, slotting cutter holders, drill chucks and morse taper holders etc.

Producing various related parts of CNC cutting tools like carbide shim, clamp, wedge, screw, pin, lever and C-ring etc; To ensure screw only holders’ quality, Selection of high quality raw materials, high precision products, good durability