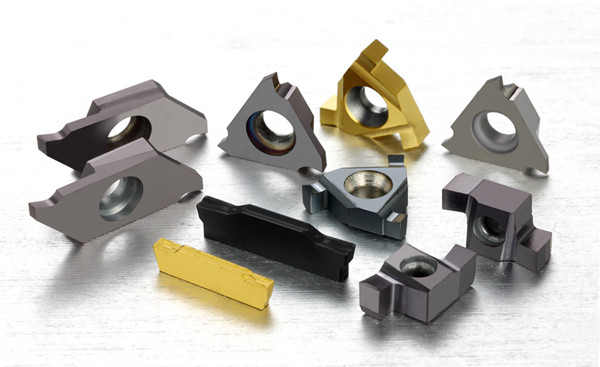

Covers the complete ISO standard line turning inserts, new type of nano materials and coating technology can ensure high performance to price ratio products, to meet the different customers' demands

From the single edge design to multi edges design not only covers the various processing forms, but also ensure excellent machinability and productivity; The inserts not only are compatible with CNC lathe, also are compatible with automatic lathe; Our inserts have pressing and grinding these two types for processing different materials and different workpieces, At the same time we can undertake non-standard customization for sepcail demands

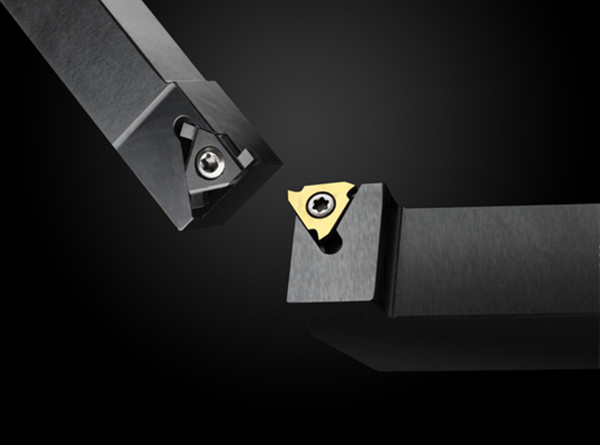

Using various of locking methods like Screw only system、Multi lock system、wedge clamp system, lever lock system and double clamp system, more processing methods and extensive range of options for the external turning tool holders.

Using a variety of structures, multiple locking methods; more and more choices of materials production for the internal turning tool holders; Using 42CrMo as the primary material of boring bar which has a high HRC, good toughness and a small shape deformed when it quenching, to ensure the good anti-vibration performance.

Be widely appicable for machining of grooving, part-off, facing and forming, and to ensure

superior machinability and high productivity.

Excellent cutting performance in wide range of boring size even in vibrated cutting condition; Utilizing precise welding technique assures longer tool life and excellent surface finish.

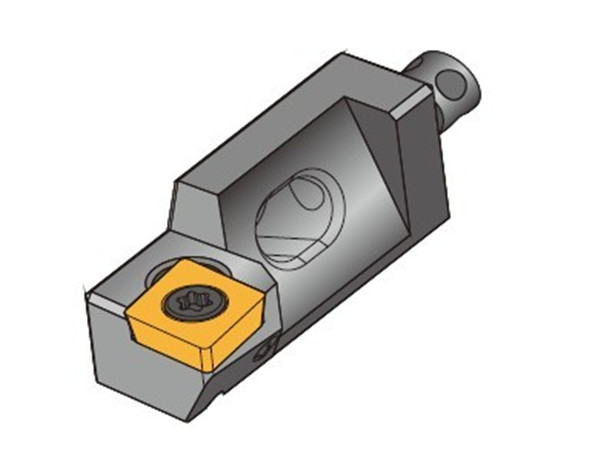

Using a variety of structures, multiple locking methods; more and more choices of materials production for cartridge; Positive rake cartridges with screw clamping are suitable for medium and light load cutting, negative rake cartridges with top clamping are used for medium and heavy load. Matching with the cutter body design, conducive to improve the cutter life, expend its’ application range; With a small screw adjustment, can achieve a good fine-turning; The good wear resistance suitable for major diameter boring tools like bridge type & step type, and fine boring tools

Widely used in high-tech, medical and small component industry, high precision; novel coating technology can increase the tool life, ensure machining accuracy; scope of application: turning, boring, copying machine, thread, chamfering and groove processing